|

Pulpa y Papel

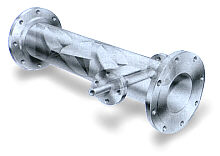

CIO2 Blench Mixer

[Descripción General|Especificaciones Detalladas]

Descripción

General

The Komax Chlorine Dioxide High Substitution

Bleaching System is now an established and reliable

technology used by modern mills worldwide. Our

unique "Triple Action Mixer" creates back mixing

which produces the high shear that is needed

to separate the pulp fibers. Fluidization of

the pulp also occurs, allowing excellent chemical

contacting which reduces chemical usage.

Inicio

Especificaciones

Detalladas

LOW AND MEDIUM CONSISTENCY CHLORINE DIOXIDE

BLEACH MIXING

SAVE THOUSANDS OF DOLLARS IN CAPITAL INVESTMENT

AND ENERGY

More and more mills in the U.S. and Canada

bleaching medium consistency stock with100%

chlorine dioxide have reduced their capital

equipment costs by installing a single Komax

fiberglass static pulp stock mixer. A low cost

Komax static mixer installed upstream of the

mechanical high-shear mixer acts as a pre-mixer.

Chlorine dioxide solution is injected into a

FRP static mixer. The four element static mixer

thoroughly mixes the CLO2 into the pulp diluting

it down before entering the downstream high

shear mechanical mixer. This enables the pulp

mill to purchase a far less expensive stainless

mechanical mixer avoiding the very high cost

of a mechanical titanium mixer. Savings will

be well over $100,000. Mills that have installed

the Komax static mixer were surprised to find

that it was providing 100% of the mixing when

they had to remove the high shear for repair.

Most of the mills have left the mechanical mixer

out of the line saving 200 h.p. The energy saved

in one year equates to four times the cost of

the Komax static. Added to the savings is zero

maintenance for ten years of service.

Mead Paper in Ohio and Michigan, as have a

number of other mills, found there was no process

change when the high shear mechanical mixer

was removed for repair. They were impressed

that the Komax static mixer was handling 100%

of the mixing. To save energy and maintenance

the high shear mixer was taken out of the system.

CHLORINE DIOXIDE MIXERS

KOMAX STATIC MIXER OR MECHANICAL M/C HIGH

SHEAR

Material of construction: FRP & KYNAR ------------------

TITANIUM

Consistency range: 2% to 15% ------------------

2% to 15%

Energy required: 15 h.p (calculated) ------------------

250 h.p. motor

Yearly energy cost: $ 4,500 * ------------------

$ 75,000 *

Operational life: 10 to12 years ------------------

3 to 5 years

Maintenance: Total life Zero ------------------

$ 100,000 +

--------------- -------------

Equipment cost: $ 22,000 U.S. $ 450,000 + U.S.

* Yearly energy cost based on $300 per year

per horse power.

To mix 100% ClO2 into 10% to 12% consistency

pulp stock there is a choice.

A) Spend $450,000 for a titanium high shear

mechanical mixer.

B) Spend $ 22,000 for a Komax Systems static

mixer.

More and more pulp and paper mills are choosing

Plan B. Some mills have left the down stream

mechanical stainless steel mixer in place. They

find since the Komax mixer is so effective the

diluted ClO2 has minimal corrosive effect on

the stainless MC mixer.

At a later date when the MC was removed for

repair, there was no change in the process because

the Komax static mixer had already achieved

100% mixing.

KOMAX STATES: WHEN IT’S MIXED IT’S

MIXED.

PULP AND PAPER MILLS THAT HAVE INSTALLED KOMAX

–ClO2 MIXERS

Mississippi River Corporation, Natchez, MS

Mead Paper, Chillicothe, OH

Mead Paper, Escanaba, MI Georgia Pacific, Crossett,

AR

International Paper, Georgetown, SC Wisconsin

Tissue Mills, Menasha, WI

Champion International, Quinnesec, MI Boise

Cascade, St. Helens, OR

St. Anne Nackawic, Nackawic, New Brunswick

Lincoln Pulp & Paper, Lincoln, NE

Finch Pruyn & Co., Glen Falls, NY Hammermill

Papers, Erie, PA

Fletcher Challenge, Mackenzie, British Columbia

Howe Sound Pulp & Paper Ltd., Port Mellon,

British Columbia

Mead Paper in Ohio (like other mills) found

their was no process change when the Komax mixer

had to handle 100% of the mixing when the high

shear was pulled out for service.

FLETCHER CHALLENGE PULP MILL

Mackenzie - British Columbia, Canada

The mill installed a Komax Chlorine Dioxide

static mixer up stream of a high shear mechanical

mixer. When the high shear mixer had to be removed

for service the engineers found there was no

change in the quality of mixing.

The Technical Superintendent stated "The

Komax static mixer has been doing the bulk of

the mixing prior to entering the high shear

mechanical mixer. For mills that feel that high

HP and brute force does the job, they should

contact the Mackenzie Pulp Mill."

The high shear mixer was left out of the bleach

line.

PARA AHORROS ADICIONALES VEA NUESTROS CALENTADORES DE VAPOR

Inicio

|